In laboratories and research facilities around the world, a quiet revolution is brewing in the realm of sustainable materials. The latest breakthrough comes in an unexpected form: biodegradable glitter derived from plant cellulose. For decades, the sparkle that adorned everything from cosmetics to crafts has been a significant environmental concern. Traditional plastic glitter, composed of microplastics, has persistently polluted oceans, harmed marine life, and lingered in ecosystems for centuries. Now, scientists and innovators are turning to nature for a solution that could finally replace this pervasive pollutant.

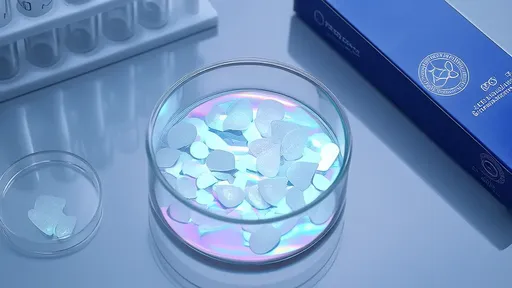

The development of plant-based glitter represents a convergence of material science and environmental stewardship. Researchers at the University of Cambridge, among other institutions, have pioneered methods to transform cellulose—the most abundant organic polymer on Earth—into vibrant, shimmering particles. By manipulating the structure of cellulose nanocrystals, they can create brilliant colors through structural coloration, similar to how butterflies’ wings or peacock feathers produce iridescence without pigments. This process not only eliminates the need for synthetic dyes but also results in a material that is completely biodegradable, breaking down harmlessly in natural environments within weeks.

What makes this innovation particularly compelling is its potential to disrupt multiple industries. The cosmetics sector, long criticized for its contribution to microplastic pollution through products like glittery makeup and nail polish, is eagerly exploring this alternative. Major beauty brands have already begun investing in and testing plant cellulose glitter, responding to growing consumer demand for eco-friendly products. Similarly, the arts and crafts industry, which relies heavily on glitter for everything from school projects to professional decorations, sees this as a game-changer. Festivals and events, often criticized for the environmental aftermath of loose glitter, could soon adopt these sustainable sparkles without guilt.

However, the transition from plastic to plant-based glitter is not without challenges. Scaling production to meet global demand remains a significant hurdle. While laboratory successes are promising, manufacturing plant cellulose glitter cost-effectively and at mass scale requires further innovation and investment. Currently, traditional plastic glitter is cheap to produce, thanks to well-established petroleum-based supply chains. Shifting to a bio-based alternative may initially involve higher costs, though economies of scale and advancing technology are expected to narrow this gap over time.

Another consideration is performance. Consumers and industries expect glitter to be vibrant, durable, and versatile. Early iterations of biodegradable glitter sometimes struggled to match the intensity and longevity of plastic versions, particularly in wet environments like cosmetics. Yet, recent advancements have addressed many of these issues. Improved coating techniques and enhanced structural designs have resulted in plant cellulose glitter that rivals its plastic counterpart in sparkle and resilience, while still breaking down safely in soil or water.

The environmental implications of widespread adoption are profound. If plant cellulose glitter replaces even a fraction of the plastic glitter used globally, it could significantly reduce microplastic pollution. Every year, thousands of tons of plastic glitter are washed into oceans and waterways, where they are ingested by marine organisms and enter the food chain. By contrast, cellulose glitter decomposes into natural components like glucose, posing no threat to wildlife or ecosystems. This shift aligns with broader efforts to combat plastic pollution, such as bans on microplastics in cosmetics implemented in several countries.

Beyond environmental benefits, the rise of plant-based glitter underscores a larger trend towards bio-based economies. It exemplifies how renewable resources can be harnessed to create high-value products without depleting finite resources or causing lasting harm. Cellulose, sourced from wood pulp, agricultural waste, or even algae, is not only sustainable but also widely available. This reduces dependence on fossil fuels and supports circular economy principles, where materials are designed to be reused, recycled, or returned to nature.

Despite the optimism, some skeptics question whether biodegradable glitter can truly displace plastic entirely. They point to existing alternatives, such as mica-based glitter, which, while natural, often comes with ethical concerns regarding mining practices. Plant cellulose glitter avoids these issues, but its success hinges on consumer acceptance and regulatory support. Education and awareness will be crucial in driving change, as many users may not yet be aware of the environmental impact of conventional glitter or the availability of sustainable options.

Looking ahead, the future of glitter appears increasingly green. As research continues and production scales, plant cellulose glitter is poised to become mainstream. Innovations in customization—such as varying particle sizes, shapes, and color ranges—will further enhance its appeal across industries. Moreover, collaborations between scientists, manufacturers, and policymakers could accelerate adoption, potentially leading to stricter regulations on plastic glitter and incentives for biodegradable alternatives.

In conclusion, the breakthrough in plant cellulose glitter marks a significant step towards reconciling human creativity with ecological responsibility. It offers a glimpse into a future where sustainability and sparkle coexist, proving that even the smallest changes can have a profound impact. While challenges remain, the momentum behind this innovation suggests that the days of plastic glitter are numbered, making way for a brighter, cleaner, and more shimmering world.

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025

By /Aug 21, 2025